Our Products

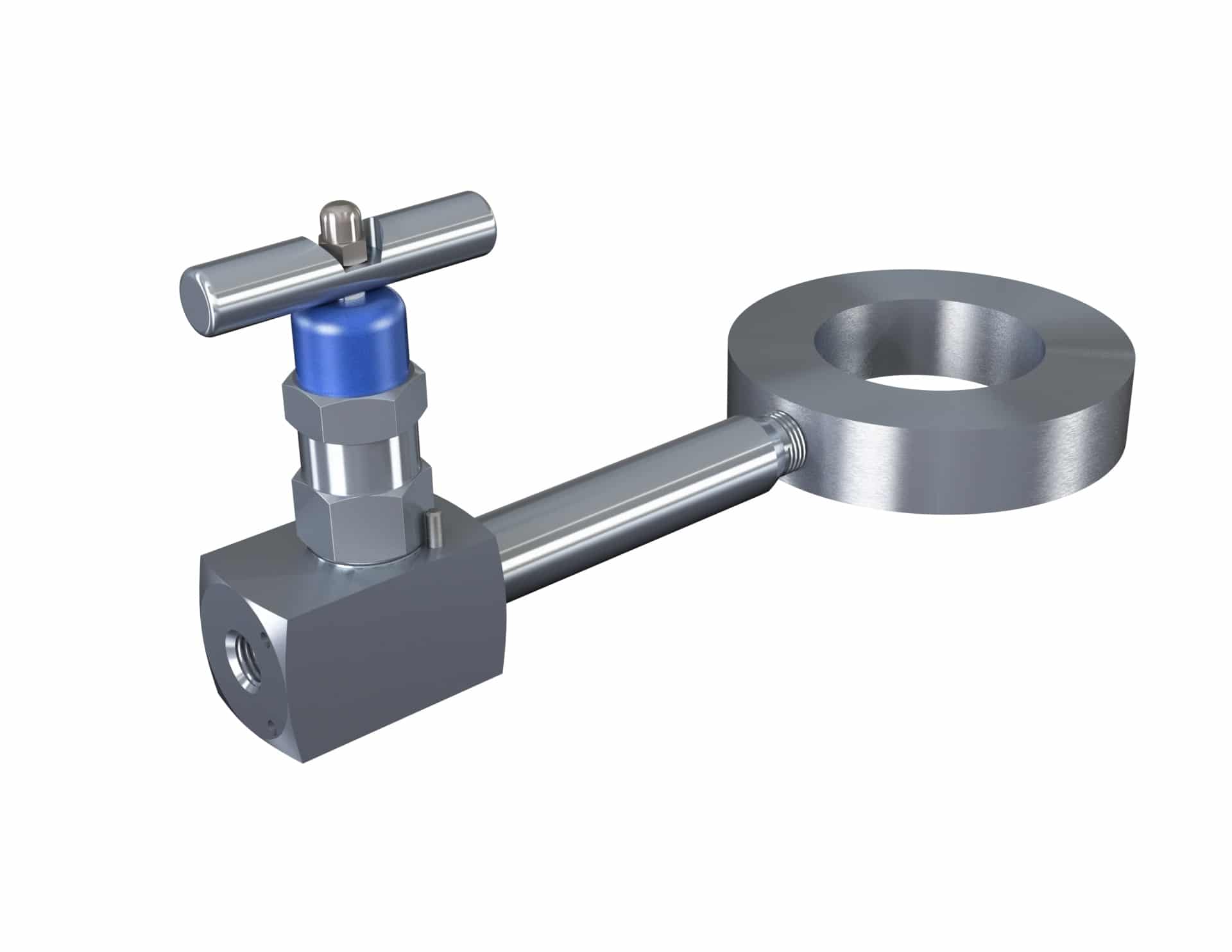

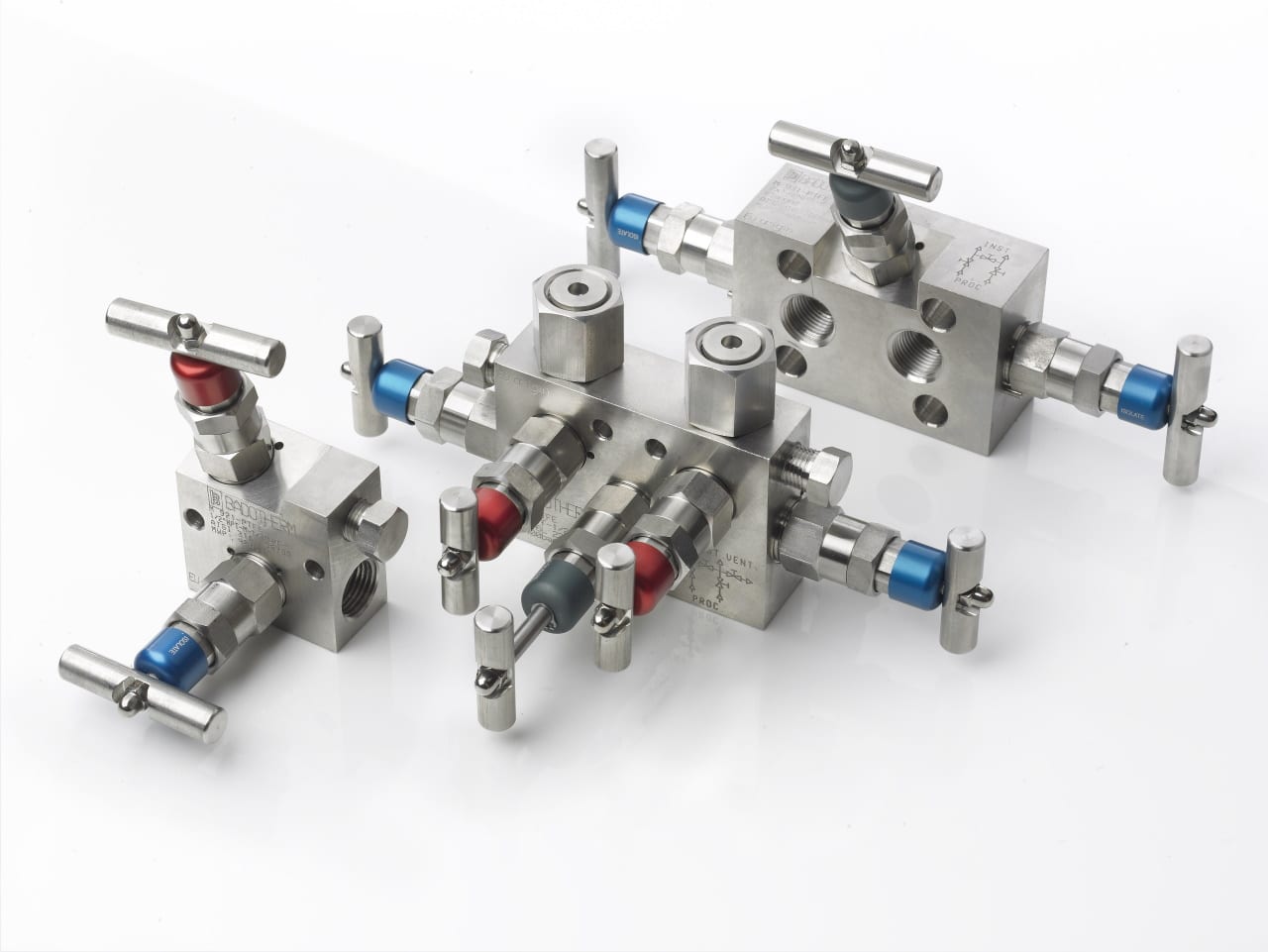

We manufacture and offer a range of products to measure pressure, temperature and level. From (differential) pressure gauges, temperature gauges and thermowells to complete Diaphragm Seal Systems with related flushing accessories.

All of our products are designed and engineered by Badotherm HQ in the Netherlands and are manufactured and assembled in Badotherm factories. This is far more complex than it seems. Manufacturing a perfect product starts with design. Not only does Badotherm design the end product, and all its components, the necessary tooling and machinery are designed in house too.